Classifications of Oil Valves in Common Use Introduction

The followings introduce classification of oil valves in common use.

1. Gate Valves

Gate valves also called as paddle valves, are one of commonly used valves. The sealing faces of disc and seat have high smoothness and same roughness. They fit each other to prevent medium from flowing through. Using pattern of backform, spring or disc can enhance sealing. Gate valves are used for cutting off medium in pipes.

Advantages: Gate valves have less fluid resistance and less force to turn on or off. Gate valves are not limited to a certain direction. It can be used under the circumstance of medium double-flow without directivity. When gate valves opened completely, the sealing face cannot be washed easily. For short face-to-face dimension, gate valves are not only suitable for small valves, but also suitable for large valves.

2. Globe Valves

Globe valves also called as stop valves, are one of the most commonly used valves. They are popular market for low friction between sealing faces when opening and closing valves. Globe valves have the advantages of long service life, low height, convenient manufacturing and maintenance. Globe valves are not only suitable for medium or low pressure, but also suitable for high pressure.

Principle: Pressure on rod makes sealing face of disc fit closely to sealing face of seat to stop medium from flowing through. Globe valves allow medium to flow in only one-way. For this, they have directivity when being installed. Face-to-face dimension of globe valves is larger than that of gate valves. Meanwhile, globe valves have low reliability of sealing for high fluid resistance when operating for a long time.

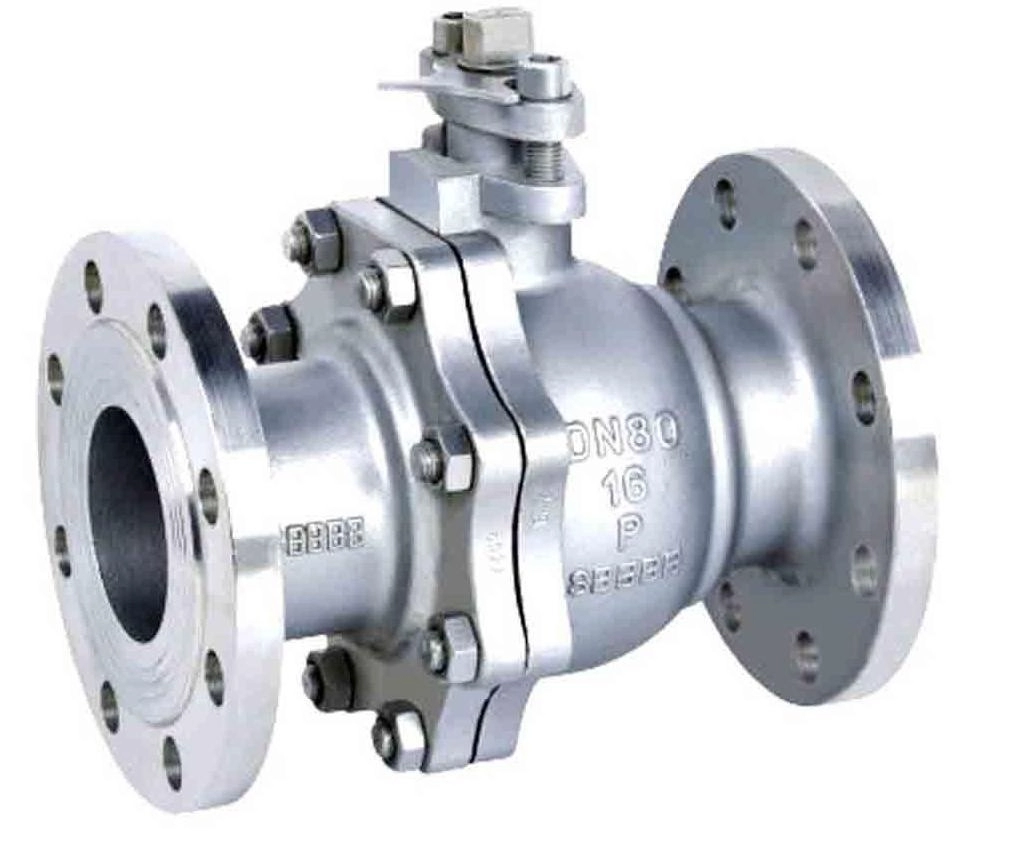

3. Ball Valves

Rotate spool to open or close valves. Ball valves have light on-off and volume. Ball valves can be used for valves having large diameter. Ball valves have the advantages of reliable sealing, simple structure and convenient maintenance. Sealing face and surface of ball are usually closed, which cannot be washed by medium easily. Ball valves are widely used in various industries.

4. Check Valves

Check valves use the pressure of fluid to open or close automatically. They are used to stop medium from back flowing, also called as cut-off valves, one-way valves and single flow valves.

5. Reducing Valves

Reducing valves are a kind of automatic valves which reduce pressure of medium to a certain value. In general, pressure after valves is less than that before valves by 50%. Reducing valves have various types, mainly classified into piston reducing valves and spring diaphragm reducing valves. Piston reducing valves utilize piston to reduce pressure. Spring diaphragm reducing valves use spring and diaphragm to balance pressure.

1. Gate Valves

Gate valves also called as paddle valves, are one of commonly used valves. The sealing faces of disc and seat have high smoothness and same roughness. They fit each other to prevent medium from flowing through. Using pattern of backform, spring or disc can enhance sealing. Gate valves are used for cutting off medium in pipes.

Advantages: Gate valves have less fluid resistance and less force to turn on or off. Gate valves are not limited to a certain direction. It can be used under the circumstance of medium double-flow without directivity. When gate valves opened completely, the sealing face cannot be washed easily. For short face-to-face dimension, gate valves are not only suitable for small valves, but also suitable for large valves.

2. Globe Valves

Globe valves also called as stop valves, are one of the most commonly used valves. They are popular market for low friction between sealing faces when opening and closing valves. Globe valves have the advantages of long service life, low height, convenient manufacturing and maintenance. Globe valves are not only suitable for medium or low pressure, but also suitable for high pressure.

Principle: Pressure on rod makes sealing face of disc fit closely to sealing face of seat to stop medium from flowing through. Globe valves allow medium to flow in only one-way. For this, they have directivity when being installed. Face-to-face dimension of globe valves is larger than that of gate valves. Meanwhile, globe valves have low reliability of sealing for high fluid resistance when operating for a long time.

3. Ball Valves

Rotate spool to open or close valves. Ball valves have light on-off and volume. Ball valves can be used for valves having large diameter. Ball valves have the advantages of reliable sealing, simple structure and convenient maintenance. Sealing face and surface of ball are usually closed, which cannot be washed by medium easily. Ball valves are widely used in various industries.

4. Check Valves

Check valves use the pressure of fluid to open or close automatically. They are used to stop medium from back flowing, also called as cut-off valves, one-way valves and single flow valves.

5. Reducing Valves

Reducing valves are a kind of automatic valves which reduce pressure of medium to a certain value. In general, pressure after valves is less than that before valves by 50%. Reducing valves have various types, mainly classified into piston reducing valves and spring diaphragm reducing valves. Piston reducing valves utilize piston to reduce pressure. Spring diaphragm reducing valves use spring and diaphragm to balance pressure.